In the late nineteenth century, American architecture in large urban centers was shaped by major technological innovations that transformed the art of building. New technologies like the curtain wall, the steel-frame skeleton, and the elevator enabled buildings to rise to new heights. New technology also increased the comfort, utility, and safety of buildings. Of particular importance were mechanical systems of heating, ventilating, and cooling air that created an artificial indoor climate. Developed first for expensive building projects before they achieved widespread use, these systems had a profound effect on everyday life. At the turn of a dial, technology promised a marvelous control over the interior environment.

More than a century later, historians continue to be inspired by the challenge of making sense of this material revolution in the built world. By any measure it was a revolution that transformed the form, the function, and the energy use of buildings. For many years our guide to these transformations has been Reyner Banham’s The Architecture of the Well-Tempered Environment (1969), a brilliant chronicle of how architects first responded to mechanical systems. Banham’s determination to write a book that privileged architects, however, meant that he left much unsaid. His effort to define a canon of progressive environmental design also kept him from looking at the broader ramifications of this technology in the landscape.

Michael Osman’s Modernism’s Visible Hand develops a new approach to the history of mechanical building technology.1 Instead of looking at iconic projects that had little influence on practice, Osman looks at the kinds of vernacular buildings that formed the bulk of building production. Focusing on American building between the late nineteenth century and the First World War, Modernism’s Visible Hand offers a social history of building technology. Drawing upon several bodies of scholarship, Osman seeks to demonstrate how this technology was related to broader patterns of social and economic change.

Osman breaks new ground in his emphasis on the importance of control in the making of the mechanically serviced building. By “control” he means the devices that regulated mechanical systems as well as the ideal that shaped their design. Through control, systems could be designed to create steady thermal conditions within a wide spectrum of buildings. Environmental control also promised to serve as a powerful tool to modernize the built environment. Modernism’s Visible Hand describes how this technology was integrated into the household and how it became essential to commerce, science, and industry. Through environmental control, the life of food products was extended, scientists simulated the natural world in the laboratory, and production processes were improved in the factory.

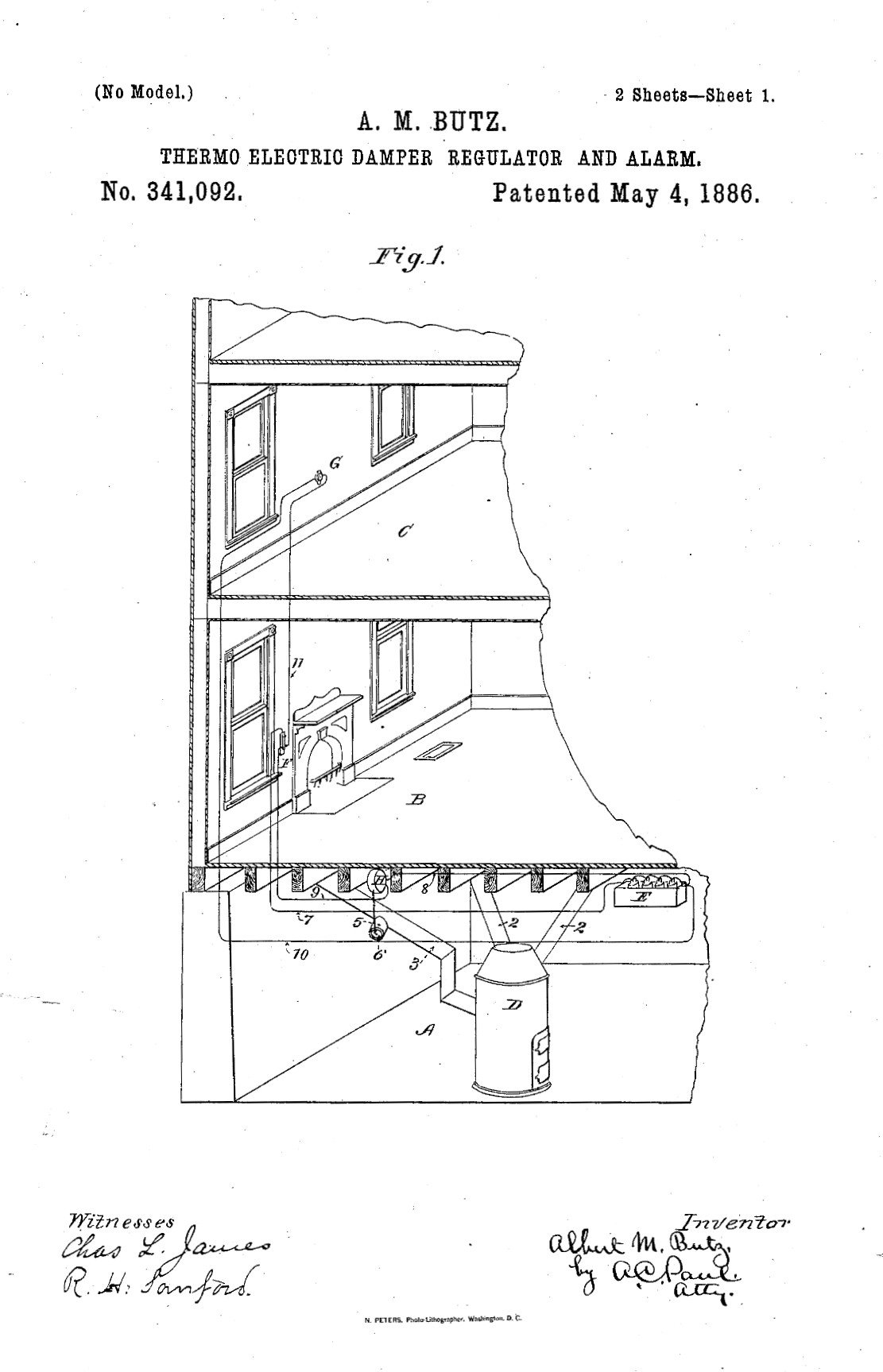

Osman’s book begins with the thermostat and how it helped redefine comfort in the home. In the late nineteenth century, most American houses were heated by burning coal. Middle-class Americans who had a large central furnace had the best system money could buy—even so, it required constant supervision. Individuals living in cold climates survived winter by making frequent trips to the basement to adjust the damper on the furnace. In 1886, Albert M. Butz, a Swiss American inventor living in St. Paul, patented an electric thermostat for domestic use. In his system a simple bimetal thermostat placed on the wall operated a spring motor in the basement that controlled the damper. It also included an alarm that rang when the temperature fell below a certain point, signaling the need for more coal.

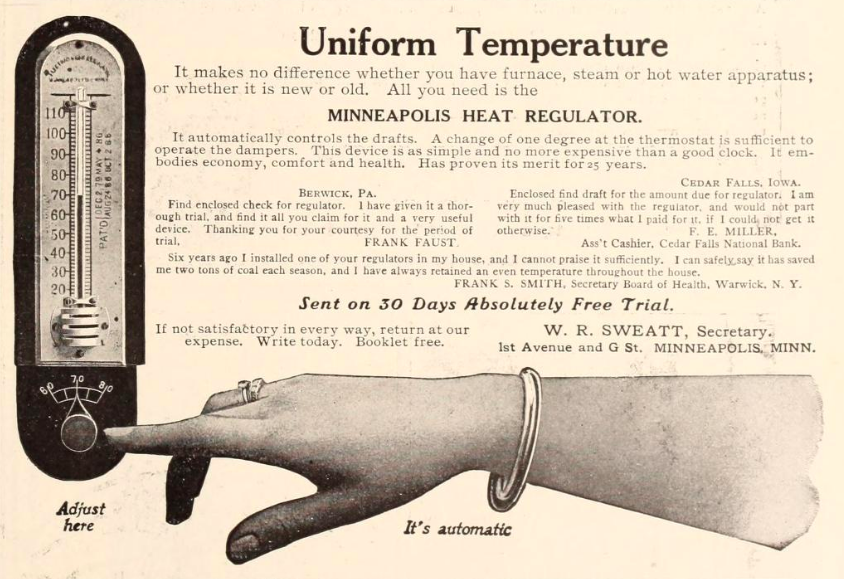

Out of this crude device grew the building control industry that aspired to install a thermostat in every American house. The company that bought Butz’s patents developed a more stylish design, worked with furnace manufacturers to ensure compatibility, and launched marketing campaigns. As Osman notes, their advertisements focused less on the device itself and more on the kind of environment it would create. The thermostatically controlled household with its uniform room temperature was modern, efficient, and sanitary. In addition to saving time and labor, the thermostat also promised to help the homeowner save fuel. Given these advantages, domestic efficiency experts promoted the thermostat as an essential tool of household management. The thermostat, alongside other labor-saving devices, promised to transform the house into a space of leisure, far removed from the world of work.

While the use of the thermostat created a comfortable room temperature in the home, the application of control to mechanical refrigeration created cold spaces. Up to the 1880s, cold storage warehouses that housed perishable food products were chilled with natural ice. Responding to the rising demand for food in urban markets, entrepreneurs and engineers developed cold storage facilities with artificial refrigeration by pumping compressed ammonia through pipes to chill rooms at precise temperatures. Mechanical refrigeration enabled the creation of colder, more stable temperatures and larger warehouses. Cold storage facilities offered wholesalers rooms chilled to optimal temperatures for preserving different kinds of food.

By the turn of the century, cold storage facilities could be found in every large city, and their effect on food consumption was wide-reaching. The cold storage industry changed consumer habits by offering a greater variety of food throughout the year. Cold storage also redefined the freshness of food. Whereas freshness was once understood as a natural quality, with the rise of cold storage, freshness could be artificially prolonged. To ensure proper practices, the federal government formed commissions to study the industry and establish regulations. Business opportunity and consumer demand overwhelmed some initial anxieties, and cold storage became an integral part of the nation’s food supply chain.

Another interesting application of environmental control, Osman shows, was developed in the vivarium. At the turn of the century, the American university had few facilities to support research in zoology. Beginning with a project at the University of Pennsylvania in 1900, specially designed laboratories were built for the study of living organisms. The vivarium at the University of Illinois, built for the zoologist Victor Ernest Shelford in 1913, represented a notable attempt to use mechanical systems within the lab to simulate the natural climate. His facility had heating, ventilation, and refrigeration systems as well as piping that supplied pond and sea water. So important were the building systems to his research that Shelford dedicated one of his books to the engineer who designed them.

Within his laboratory, Shelford created simulations of seasonal changes in weather to better understand the life cycle of different organisms. Osman mentions that Shelford’s study of the chinch bug was especially important. In the early twentieth century, outbreaks of this insect decimated grain fields across the Midwest. Shelford’s interest in creating experiments to gather information that could be used to protect farmland from pests illustrates how scientists envisioned commercial applications for their work. As Osman also notes, Shelford’s dependence upon complex and expensive machinery gave his research the character of an industrial enterprise that “required investors, laborers, and management.”

The most complex application of environmental control occurred in the factory, where manufacturers went to great lengths to engineer their plants for maximum production. Machinery generated huge amounts of heat, humidity, and exhaust air. Many industrial processes needed to be conducted within precise thermal conditions to maintain quality control. The health of workers also needed to be taken into account, insofar as fatigue slowed production. The challenge of designing factories that accounted for these variables stimulated the growth of a new branch of engineering. Trained in scientific management, the industrial engineer treated the design of buildings, their systems, and the work process as a single problem.

As Osman explains, the rationalized factory was a machine closely involved in the production process. To visualize the new factory, engineers developed a new graphic language of flow diagrams that described the ideal relationship of machinery, men, and materials on the shop floor. Industrial engineers developed more efficient factory layouts and used machinery to create an ideal environment for production, but their effort to reengineer the work process was met with resistance. Throughout the early twentieth century, management and workers struggled against one another for control over the workplace.

Osman concludes his book with a look at how the managerial philosophies that guided factory design were applied to architecture offices in the early twentieth century. Many of the largest architectural firms of the day occupied spaces that were clearly influenced by the ideas of office efficiency experts. In their treatises on office management, they argued that proper lighting, heating, and ventilation, alongside the careful arrangement of desks, would ensure an efficient flow of paperwork and a productive workforce. Lee Galloway, one of the major figures within this movement, used a picture of the Larkin Building atrium as the frontispiece of his book.

Albert Kahn’s office in Detroit serves as a fitting case study of the early twentieth century design firm. Kahn personally designed the firm’s quarters that occupied a top floor in a downtown office building. Internal communication systems kept the firm’s separate departments in touch. Glass partitions enabled supervisors to keep an eye on the draftsmen. Unlike many offices, which kept a few watercolors and plaster casts on the wall as reminders of the atelier, Kahn’s offices were bare. There was little to distinguish the office from the drafting department of a large utility company or shipbuilding firm.

Osman’s central claim is that the rise of the mechanically regulated interior at the turn of the century expressed a deeper drive to use technology to regulate the built environment. The inventors, engineers, scientists, and entrepreneurs who developed this technology saw themselves as part of a vanguard of technical progress that was modernizing the nation, its homes, its workplaces, and its infrastructure. Viewed within the larger context of the history of technology, they were what Thomas P. Hughes has called “system-builders.” While the characters Osman describes were creating building systems, others were building the networks that supplied them with energy. By the early twentieth century, such system builders had assumed an outsized role in the shaping of the landscape. Although many of their creations were often hidden from view, American society was increasingly dependent upon them.

Osman’s book is an imaginative study that enriches our understanding of an aspect of the built environment that is often taken for granted. His book is also a valuable contribution to a small but growing body of scholarship on the history of building systems. Addressing the history of home heating systems over the course of the nineteenth century, Sean P. Adams’s Home Fires (2014) chronicled the development of the “industrial hearth” and the switch from wood to coal as the primary source of fuel. Gail Cooper’s Air Conditioning America (2002) traced the rise of air-conditioning from the early twentieth century to the postwar era. As these books demonstrate, the pace of change has been dramatic. In the early nineteenth century, Americans heated their homes by tending the fire. A little over 150 years later, millions were living and working within environments of “manufactured weather.”

Today most American households use a thermostat to control a central heating or cooling system that circulates air at a comfortable room temperature. The cold storage industry has grown into a colossus with hundreds of millions of square feet of space, and millions more are on the way with the growth of online grocery shopping. Scientific laboratories have become an essential and, in many cases, the dominant feature of the American campus. The pharmaceutical, electronics, and chemical industries are dependent upon the use of “clean rooms” that filter air with a high degree of precision.

With the growing concern about the environmental impact of buildings, the subject of building systems has again become an important subject of debate. As architects attempt to rethink how we build in an era of climate change, Osman’s book asks us to confront what he calls the “the relentless myth of automatic processes that change our buildings, our cities, and the lives we live within them.” With the development of new building technology little more than a century ago, our ability to engineer the interior environment expanded dramatically—the consequences of which we are only now beginning to understand.

-

Michael Osman, Modernism’s Visible Hand: Architecture and Regulation in America (Minneapolis: University of Minnesota Press, 2018). ↩

Alexander Wood is a PhD candidate at Columbia University, where he studies the history of American architecture, urbanism, and landscape. His dissertation, Building the Skyline: Architecture, Construction, and Labor in New York City, 1880–1935, chronicles the city-building process in New York from the Gilded Age to the Great Depression. He received an SMArchS degree from MIT and a BArch from the Cooper Union.